When embarking on a new project, whether it's construction, event planning, or storage needs, many individuals and businesses are discovering the versatility of using a conex container. These sturdy steel containers, originally designed for shipping, have emerged as a popular solution for a wide array of applications. With their robust construction and ample space, conex containers provide a practical choice for organizing tools, materials, and equipment while ensuring safety and security against environmental elements.

As this trend continues to grow, it is essential to understand the best practices for utilizing a conex container to maximize its benefits. From choosing the right size container to optimizing interior organization, knowing how to effectively use a conex container can greatly enhance the efficiency and outcome of your project. In this guide, we will explore ten essential tips that will empower you to make the most of your conex container, transforming it into a valuable asset for your specific needs. Whether you are new to using containers or looking to improve your existing setup, these insights will set you on the path to success.

When considering a Conex container for your next project, it is crucial to understand what these structures are and the advantages they offer. Commonly utilized for shipping and storage, Conex containers—also known as shipping containers—are robust, steel-built units that come in various sizes, typically 20 to 40 feet in length. According to the Worldwide Container Market report by Mordor Intelligence, the global shipping container market is projected to reach $10.5 billion by 2026, highlighting the growing reliance on these containers for various applications beyond mere storage solutions.

The versatility of Conex containers is a game-changer for projects requiring temporary or durable storage. They can easily be modified to serve as onsite offices, workshops, or even living quarters, depending on the project requirements. A report from MarketsandMarkets indicates that the modular construction market, which includes Conex container conversions, is expected to grow at a CAGR of 6.4% from 2021 to 2026, signaling an increasing acceptance and adaptation of these units within diverse industries.

Understanding the basic specifications and advantages of Conex containers can help you make informed decisions about how they can best serve your project needs, whether for construction, event management, or emergency relief operations.

When embarking on a project that involves the use of a Conex container, selecting the right type is crucial to meet your specific needs. Conex containers come in various sizes and configurations, typically measuring 20 or 40 feet in length. The choice largely depends on the volume of goods you intend to store or transport. For smaller projects, a 20-foot container may suffice, providing ample space without overwhelming your available area. Conversely, larger projects with heavy material requirements may necessitate a 40-foot container to accommodate the volume.

Additionally, consider the features of the containers available to you. Standard dry containers are excellent for general storage of non-perishable items, while refrigerated containers are essential for temperature-sensitive goods. If your project is set in a location prone to harsh weather, opting for containers with added insulation or weatherproofing can greatly extend the lifespan of your assets. Furthermore, specialized containers like high-cube options can offer extra vertical space, making them ideal for tall items. By carefully assessing your project’s requirements against the various types of Conex containers, you can ensure an effective and efficient solution that aligns with your operational goals.

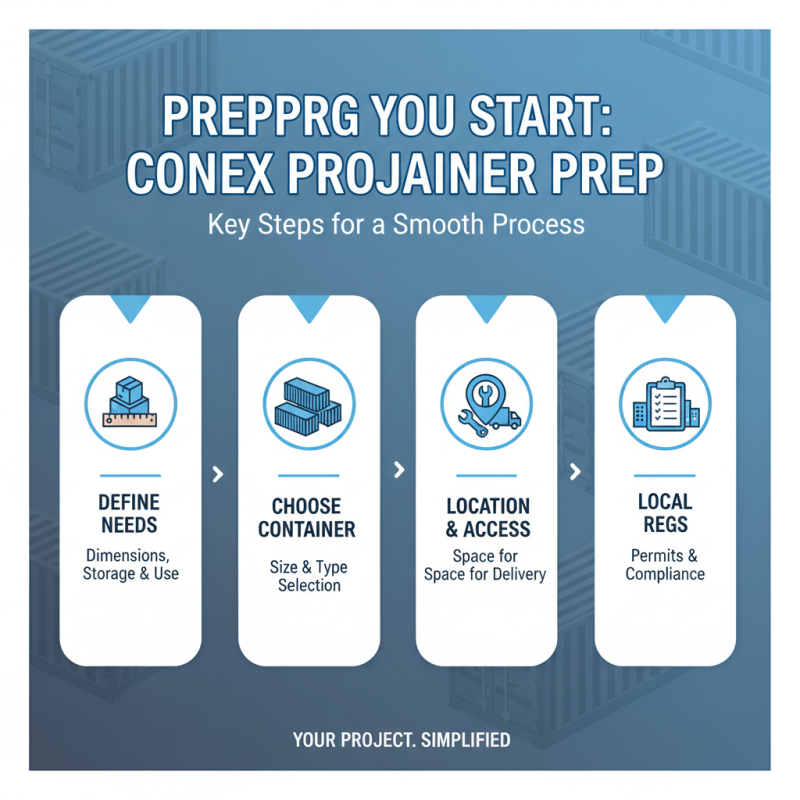

Before using a Conex container for your project, proper preparation is crucial to ensure a smooth and efficient process. Start by determining the specific needs of your project, including dimensions, storage requirements, and intended use of the container. This will help you select the right size and type of container for your needs. Consider the location where you will be placing the container; ensure there is enough space for the container to be delivered and accessed. Additionally, check local regulations regarding the placement of containers to avoid any compliance issues.

Next, inspect the container thoroughly before use. Look for any signs of damage or wear that may affect its structural integrity or suitability for your project. It's also wise to clean the interior to eliminate any contaminants, especially if the container will be used for storage or as a workspace. If necessary, plan for modifications or enhancements that may be required, such as ventilation or insulation, to make the space more functional. Taking these steps will help ensure that your Conex container is ready to meet the demands of your project effectively.

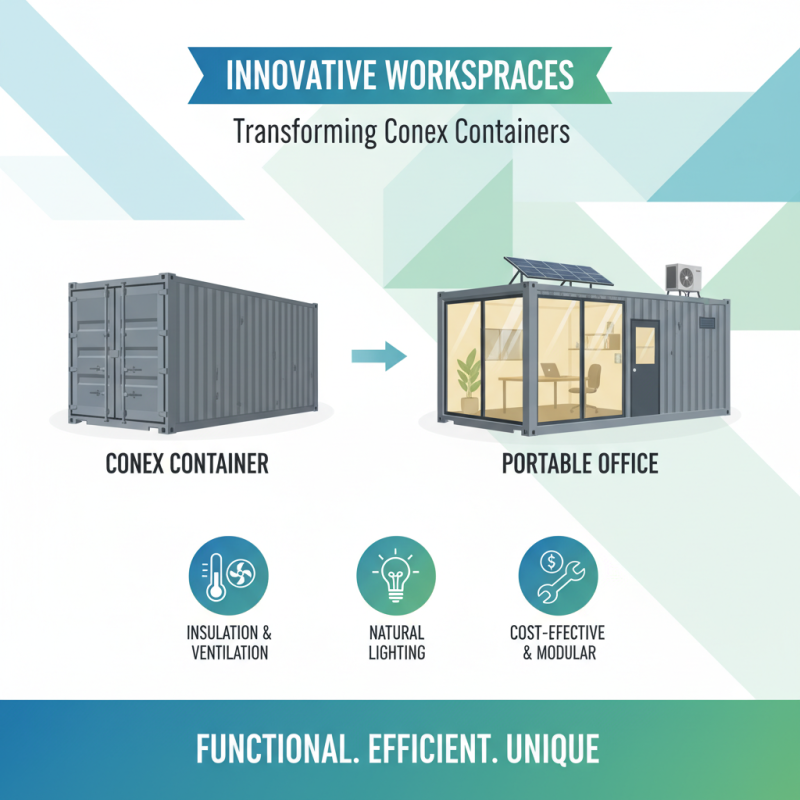

A Conex container, often recognized for its robust design and versatility, can be transformed into various innovative solutions for both personal and commercial projects. One effective way to utilize a Conex container is by converting it into a portable office space. With the right insulation, ventilation, and lighting, these containers can be adapted to create functional work environments that offer a quiet retreat from the distractions often present in conventional offices. This approach not only maximizes space efficiency but also minimizes construction costs, making it an appealing option for small business owners and freelancers seeking a unique workspace.

Another creative application for a Conex container is as a pop-up retail unit. The modular nature of these containers allows them to be easily modified to suit different branding needs, enabling entrepreneurs to set up shop in diverse locations with minimal setup time. By adding windows, doors, and signage, a Conex container can be transformed into an eye-catching storefront for seasonal sales, food vendors, or temporary exhibitions. Additionally, the secure structure of these containers ensures that merchandise remains protected from the elements, allowing for a flexible business model that can adapt to various market demands.

When working with a Conex container, safety should take precedence throughout your project. Before you even begin, it's imperative to inspect the container for any structural damages or potential hazards. Look for signs of rust, sharp edges, or hazardous materials left by previous users. Ensure that you are equipped with the appropriate personal protective equipment (PPE), such as gloves, hard hats, and steel-toed boots, to protect yourself while handling the container.

One essential tip during your project is to maintain proper ventilation within the container, especially if you’ll be using it for storage or as a workspace. Stale air can lead to the accumulation of harmful gases, creating a health risk. Regularly check for adequate airflow and consider installing vents if the container will be used frequently. Additionally, be mindful of your layout and storage methods to prevent any potential tipping hazards, ensuring that all items are stored securely and that pathways remain clear.

Finally, always have a first aid kit readily available and ensure that all workers are educated on basic emergency procedures. Knowing how to respond to incidents can drastically reduce the risk of severe accidents. Implementing these safety measures not only protects you and your team but also contributes to the overall success of your project.

| Tip Number | Tip | Description | Safety Measures |

|---|---|---|---|

| 1 | Check Structural Integrity | Ensure the container is free of rust and damage. | Inspect for leaks and structural weakness. |

| 2 | Ventilation | Ensure proper airflow to prevent moisture buildup. | Install vents or keep doors partially open. |

| 3 | Weight Distribution | Distribute loads evenly to avoid tipping. | Use appropriate loading techniques. |

| 4 | Secure Cargo | Ensure all items are securely fastened. | Use straps, nets, or crates. |

| 5 | Safe Entry/Exit | Use ladders or steps for safe access. | Avoid climbing on unstable surfaces. |

| 6 | Electrical Safety | Avoid using non-rated electrical equipment. | Use explosion-proof lights if necessary. |

| 7 | Fire Safety | Keep flammable materials stored safely. | Install fire extinguishers nearby. |

| 8 | Regular Inspections | Conduct routine check-ups for safety. | Schedule inspections monthly. |

| 9 | Training | Ensure workers are trained in safety procedures. | Conduct regular safety drills. |

| 10 | Emergency Plans | Have protocols for emergencies in place. | Create exit plans and communicate clearly. |

Registered in England & Wales No. 2786496

Registered office at: 337 Tanworth Lane,

Shirley, Solihull, B90 4DU

Registered for VAT, registration No.

GB 655 1347 38

Location: Nationwide

Not Available for Hire

We can deliver for a cost please ask and send us post code.

13 tread

14 tread

15 tread

Location: Nationwide

Not Available for Hire

Call for an instant quote!

Location: Nationwide

Not Available for Hire

We can deliver for a cost please ask and send us post code.

Hallway leading into:

Transport can be arranged please ask.

Location: Nationwide

Not Available for Hire

Call for an instant quote!

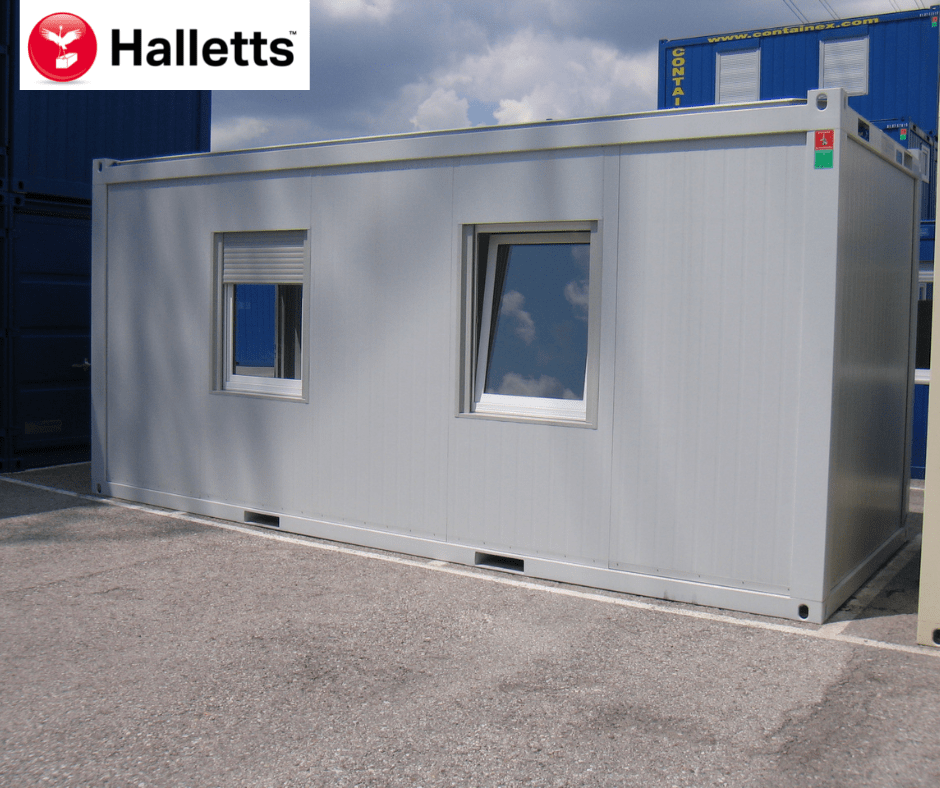

20ft x 8ft Container Conversion Retail Shop

UPVC Double glazed Windows + French Doors

Slat Wall for retail fixings and Merchandise

Electric Chrome Sockets, led lighting and heating.

Laminate Flooring

12 months Warranty

Maintenance call out package included

Less than 2 years old

Still in Brand New Condition

Fully refurbished

Colour light grey

Slate grey anthracite upvc double glazed windows

Location: Nationwide

+ VAT

Not Available for Hire

Call for an instant quote!

Fully Insulated with electric sockets, spot lighting, and heating

Wood Flooring

UPVC Sliding Door + Windows

Lead Time for build 6-8 weeks

Location: Nationwide

+ VAT

Not Available for Hire

Call for an instant quote!

Fully Insulated with electric sockets, spot lighting, and heating

Wood Flooring

Aluminium Bi Fold Doors

Fully wrapped in larch cladding

Lead Time for build 6-8 weeks

Location: Nationwide

+ VAT

Not Available for Hire

Call for an instant quote!

Fully Insulated with electric sockets, spot lighting, and heating

Wood Flooring

Feature Clad Wall and Ceiling

UPVC Double glazed French Doors

Fully wrapped in larch cladding

Lead Time for build 6-8 weeks

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

10ftx8ft – £5950 + Vat / 16ftx8ft – £7950 + Vat / 20ftx8ft – £9000 + Vat / 24ftx8ft – £12000 + Vat / 30ftx8ft – £13500 + Vat

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

Quantity: ∞

EX VAT

Not Available for Hire

Call for an instant quote!

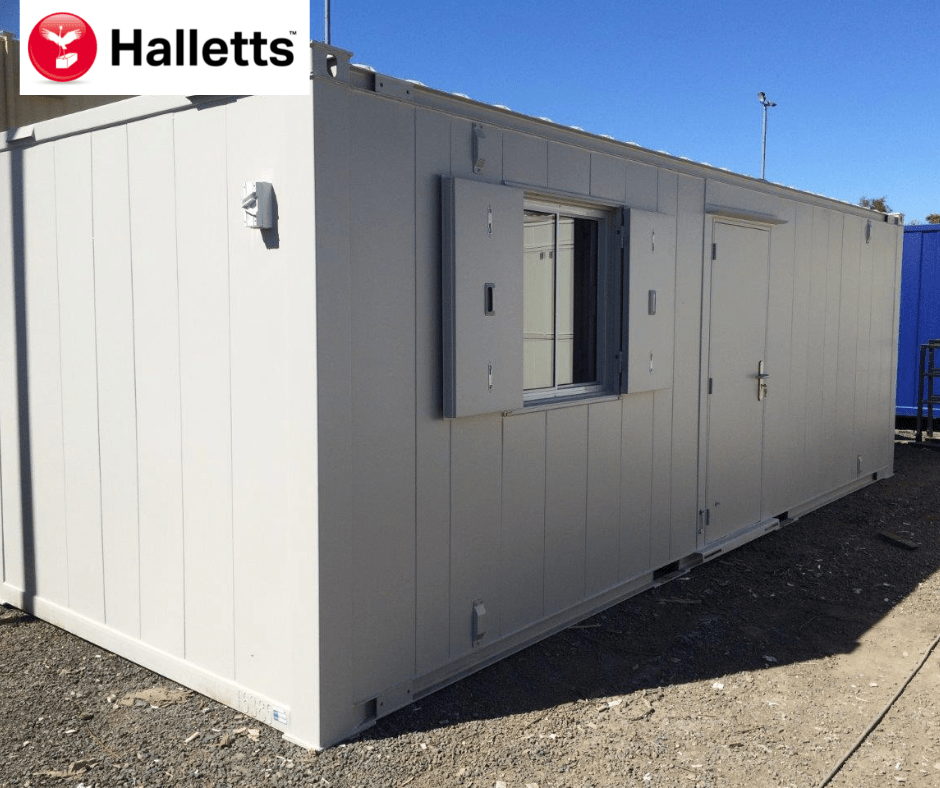

• Reinforced doors and windows with secure locking

• Open plan with electric sockets and lighting

• Ral Code Colour of choice

• Any Extras available : Canteen, Partitions, Toilets.

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

• Reinforced doors and windows with secure locking

• Open plan with electric sockets and lighting

• Ral Code Colour of choice

• Any Extras available : Canteen, Partitions, Toilets.

• Reinforced doors with secure locking

• Sink and water boiler included

Location: Nationwide

Quantity: ∞

EX VAT

Not Available for Hire

Call for an instant quote!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Get a Quick Container Quote Now!

Location: Nationwide

EX VAT

Not Available for Hire

Call for an instant quote!

Get a Quick Container Quote Now!

Get a Quick Container Quote Now!